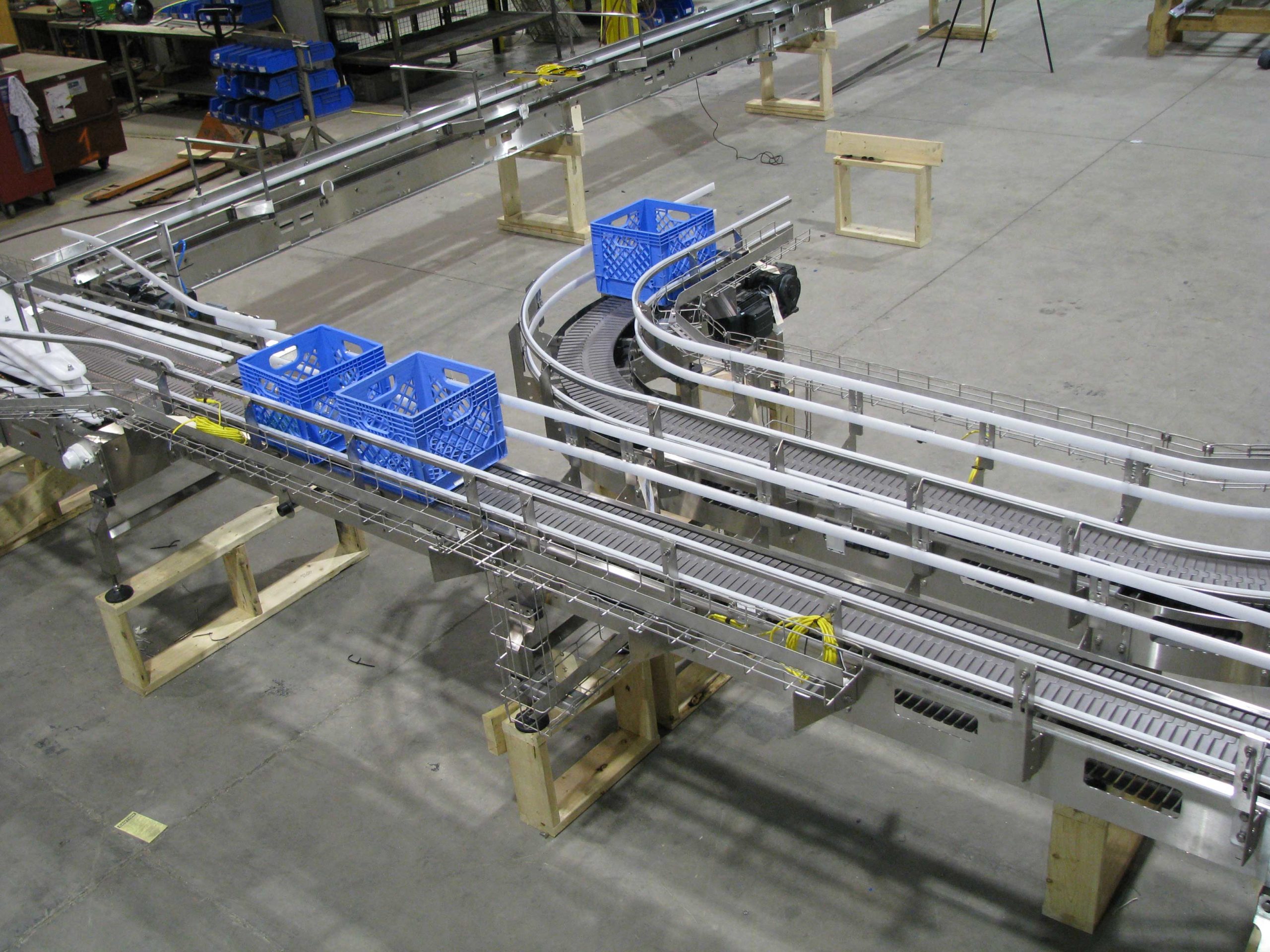

People can use Conveyor systems in factories, warehouses and other industrial workplaces to transport materials. They can also use them to move products from one place to another. We can classify Conveyors into two types: continuous and intermittent.

Continuous conveyors have a belt that moves continuously, while intermittent conveyors have a belt that moves intermittently. A conveyor system is made up of four basic components: the drive mechanism, the belt or chain, the idler rollers or pulleys and the guide rails or slides.

Conveyor belts are one of the most important parts of any warehouse. They are used to move goods from one location to another. When it comes to choosing a conveyor belt, there are many things that need to be considered. The size, the durability and the type of conveyor belt all play a vital role in how well the belt performs.

The size of the belt is determined by how much weight it can hold and what kind of items will be traveling on it. Durability is also a key factor as this will determine how long your belt will last before needing replacement or repair, which can be costly for any business. Lastly, there are different types of belts available; some move horizontally while others move vertically or in a circular motion.

Complete this form and our team will answer as soon as possible. All fields required.

RCMH provides expert warehouse solutions, specializing in space planning, permits, and quality pallet racking to optimize efficiency and storage capacity.

2025 RCMH MATERIAL HANDLING. All Rights Reserved